Home – Computing – Fitness – How to… Motivation – Product Reviews – Stories – Tips – Disclaimer.

Why do we use a Washer?

Without a washer only the head of the bolt or screw holds down the work-piece and also can break into the likes of wood or brittle surfaces.

Using a washer widens the area being pressed together so the force covers a wider area.

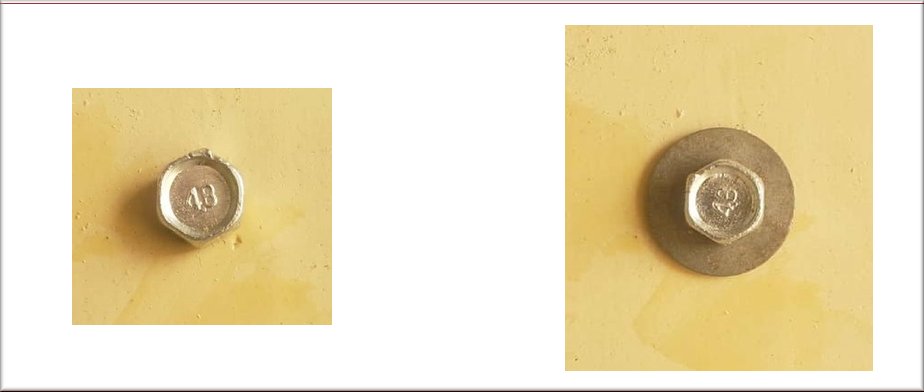

The bolt on the Left presses down only on the area that the head covers.

The same bolt on the Right presses down on a larger area due to the washer between the Bolt Head and the material being bolted, the same bolt does a bigger job with a washer. Because it is a larger area the washer is distributing the pressure over a larger area.

Sometimes a washer can be used as a ‘spacer’ to fill a gap. For instance if the bolt has a thread that only goes so far, but not far enough, and it is two millimeters short a 3-4 millimeter thick washer can be used to make up the gap and the work is tightened.

If there is damage to the surface of the work where a bolt is a nice clean shiny washer can be used to cover over the damage and looks professional.

I have known of people drilling holes, putting in a bolt and washer where it is not needed just so that it covers a hole and still looks professional.

Some washer are made of plastic or rubber material. The rubber washer can seal a bolt and surface so no water gets through.

Some washers are used to help absorb vibrations, for instance the washer is made or part made from Sorbothane.

If in doubt, use a washer.

Above is a photo of a Spring Washer. They push outwards and in areas where there is vibration and the bolt could come loose the Spring Washer helps hold the bolt and nut all together.

There are other washers with teeth on them that grab into the work material and hold the nut and bolt steady while also limiting the chances of the bolt coming loose.

I hope that this helps you to understand why we use washers on bolts and how useful they are.

All the best from

James M Sandbrook.

24th of March, 2021.

– Home –

Character. Character Assassination. Children. Computing. Crosswords. Driving. Education. Electronics. Garden/Yard. Good Man Images. Fitness/Health. Homeschooling. House Ideas. How To. Interesting & Helpful Videos. iPad. Jokes. Kitchen/Cooking. Love, Courting and Marriage. Mechanics/Machines. Motivation/Advice. Movies. Music. Narcissism, Abusers & Covert Manipulators. NZ. OOS/RSI. Parenting Idea’s, Tips, Thoughts etc. People. Personal Care. Parenting & Children – Notes. Photography. Plumbing. Poetry. Product Reviews. Projects. Proverbs. Religion. Reviews.

Sewing. Skills/Hobbies. Slang. Stories & Books. Tips.

Tools. Toxic Parenting. Whats It Mean? Women. Words. Woodwork. Woodwork Basic Lessons.

===

===

© 2021-2025 – James Martin Sandbrook. All Rights Reserved.